China manufacturer asphalt plant 40-320t/h asphalt mixing plants price

-

Supplier: Henan ZOOMLINE Machinery Co., Ltd. -

Region: Henan, China -

Contact: Mr ZOOMLINE MACHINERY -

Price: $150000.00 /set -

Min. Order: 1 set

| Machinery Test Report: | Provided; | Pneumatic system: | GERMAN; |

| Marketing Type: | Ordinary Product; | Power: | 150-800kw; |

| Weight: | asphalt plant model; | Port: | Sea Port: Qingdao/Shanghai/Tianjin; |

| Local Service Location: | Egypt,Indonesia,Pakistan,Russia,Thailand,Bangladesh,Kazakhstan,Ukraine,Kyrgyzstan,Uzbekistan; | Applicable Industries: | Building Material Shops,Construction works ; |

| Packaging Detail: | China manufacturer asphalt plant 40-320t/h asphalt mixing plants price need: 40HQ Containers; | UNIQUE SELLING POINT: | High operating efficiency; |

| Warranty: | 1 Year; | Voltage: | 220V/380-50HZ; |

| Condition: | New; | Package Preview: | ; |

| Brand Name: | ZOOMLINE asphalt plant; | Capacity: | 40-320TPH; |

| Weighing system: | METTLER TOLEDO,USA; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Installment; |

| Operation: | Auto & Manual; | Showroom Location: | Egypt,Indonesia,Pakistan,Russia,Thailand,Bangladesh,Kazakhstan,Ukraine,Kyrgyzstan,Uzbekistan; |

| Place of Origin: | Henan China; | Type: | Batch mix type,Bitumen mix plant; |

| Burning system: | EBICO,ITALY; | Product name: | China manufacturer 40-320t/hr asphalt mixing plants price; |

| Video outgoing-inspection: | Provided; | Mixer: | 500-4000kg/batch; |

| Core Components: | PLC,Motor,Pump; | Supply Spareparts: | Within 10 years; |

| After-sales Service Provided: | Video technical support,Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service; | Supply Ability: | 10 Set/Sets per Month; |

| Control system: | SIEMENS,GERMAN; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Warranty of core components: | 1 Year; | Dimension(L*W*H): | asphalt plant model; |

| Certification: | CE,ISO,EAC; |

China manufacturer asphalt plant 40-320t/h asphalt mixing plants price

1.Simple equipment structure, flexible layout, easy maintenance. Modular design, easy to installation and move.

2.All conveyor belts are ring-bonded ,longer than belt buckle, no mechanical failure (belt buckle is easy to break).

3.Automatic lubrication - key components are equipped with automatic lubrication device (Lincoln),it was controlled by control room. To ensure that each bearing lubrication in place, reduce manpower, reduce the occurrence of failure.

4.All solenoid valves and cylinders are used in Germany Festo, practical, stable quality (resistance to dust, strong temperature).

5.Mixer wear parts using CrMo alloy, effective life more than 100,000 batches. Adopt double-axis dual-motor drive, high efficiency, low energy consumption. Asphalt with the second measurement of high pressure spray, stir quickly and evenly.

6.International first-line brand of electronic control components. PLC supporting remote detection (through the Internet can be remote on the system fault detection, recovery).

7.Big Dust removal area, and supporting a dust humidifier, to prevent powder warehouse flying.

8.Machining parts are own processing, quality, delivery period are guaranteed, parts supply convenient and quickly in the future.

9.All asphalt plant machine has test assembly and trial running before living the factory. To make sure each parts working reliable, connected correctly. Ensure the quality of the equipment which is stable and reliable.

10.Variety kinds of fuels to choose, for different regions, different users, you can choose coal, heavy oil, diesel, gas and other fuels, we have a wealth of construction experiences on each fuel using, we can provide perfect solutions to customers.

ZOOMLINE asphalt plant have been used in highways, high-grade highways, urban roads and airport construction and got high reputation for their excellent performance. Nowadays, our asphalt plant products have been sold to Russia, Cambodia, Bangladesh, Egypt, Pakistan, Uzbekistan, Kazakhstan, Kyrgyzstan, Ukraine, Georgia, Indonesia, Belgium and Thailand etc.

Technical parameters of ZAP-S series 40-320t/h asphalt mixing plant:

| Style | ZAP-S40 | ZAP-S60 | ZAP-S80 | ZAP-S100 | ZAP-S120 | ZAP-S160 | ZAP-S200 | ZAP-S240 | ZAP-S320 |

| Rated capacity(T/H) | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 240 | 320 |

| Total power(kW) | ≈150 | ≈180 | ≈270 | ≈300 | ≈390 | ≈500 | ≈570 | ≈640 | ≈800 |

| Mixer volume(kg) | 500 | 750 | 1000 | 1300 | 1500 | 2000 | 2500 | 3000 | 4000 |

| Cold aggregtae kinds | 4 | 5 | 6 | ||||||

| Vibration screen | Uniaxial circular vibrating screen | Biaxial linear vibrating screen | |||||||

| Mixing cycle | 45S | ||||||||

| Fuel consumption | ≤6.5kg/t finished product | ||||||||

| Fuel type | Heavy/ Light oil | ||||||||

| Control mode | Manual/ Automatic | ||||||||

| Finished product temperature | 140-180°C | ||||||||

| Aggregate weighting precision | ±0.5%(Dynamic) | ||||||||

| Mineral weighting precision | ±0.5%(Dynamic) | ||||||||

| Bitumen weighting precision | ±0.25%(Dynamic) | ||||||||

| Dust control way | Primary cyclone dust collection , secondary bag dust collection | ||||||||

| Exhaust emission concetration | ≤20mg/Nm3 | ||||||||

| Finished product bin | Bottom placed / side placed | ||||||||

| Optional | |||||||||

Asphalt mixing plant mainly including cold feed systems, drying system, burning system, hot material enhance, vibrating screen, hot material storage bins, weighing mixing system, bitumen supply system, powder supply system, dust removal system, finished product storage bin, control system and other parts.

|

Cold aggregate system

1. Uniform and exact feeding of cold aggregates is necessary for the production of first-rate asphalt mixture.

2. Our belt feeder equipped with frequency control which could change speed according to the capacity and ratio.

|

|

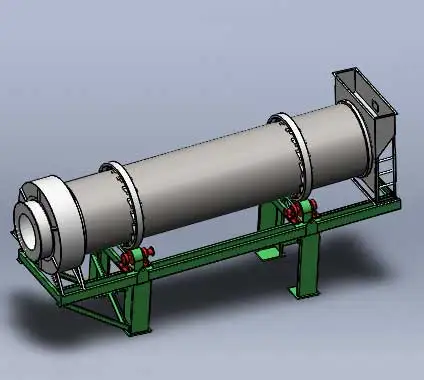

Drying system

1.The dryer drum adopts high quality thermal insulation external material and covers with stainless steel which ensures the insulation performance. And the whole design is neat and clear.

2.The inner aggregate blade adopts boiler steel plate which is connected with bolts, with long service life and easy maintenance.

3. Friction drive system could work smoother with low noise.

4. Roller, roller shaft are all made of steel alloy which could help the thermal expansion of the cylinder force more evenly. This design solved the elastic plate heat cracking problem.

|

|

|

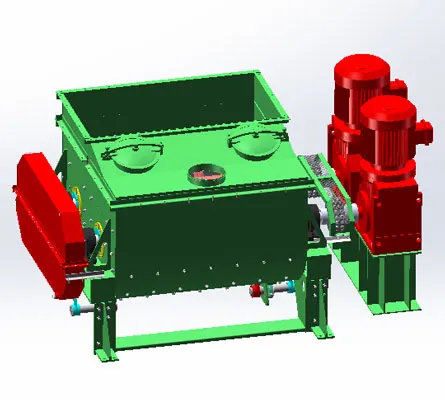

Mixing system

1.Double shaft and double helix, long axis and short arm, shallow structure.

2.The internal liner and vane use high wear-resistant alloy cast steel, with long service life.

3.The discharge door is equipped with electric or thermal oil heating to prevent bonding.

4.Bidirectional spiral blade could mix in three dimensional spaces.

5.Upper and lower separation design for convenient maintenance.

6.Using world famous brand reducer and the failure rate is greatly reduced.

|

|

Vibrating system

1.Specifically designed for asphalt mixing plant, the special vibrating screen can better meet the requirements.

2.The high wear-resisting screen mesh (65 MN) with longer service life and lower maintenance costs.

3.The optimal designed shield can effectively prevent the dust spillover and is more environmentally friendly.

4.Screen using drawer-type structure which makes the replacement fast and convenient.

5.The front shield with roller support makes back and forth motion easily.

|

|

|

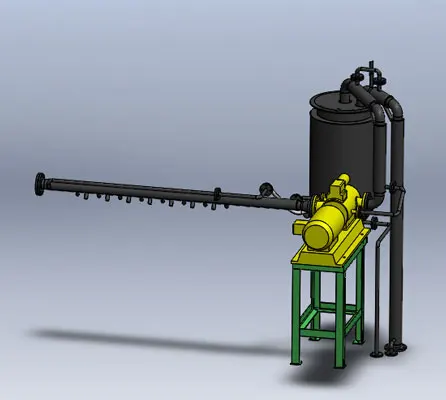

Weigh bucket system

1.Bitumen pump high pressure spraying makes the distribution of asphalt more evenly.

2.The outside of bitumen tank is equipped with insulation device to prevent heat loss.

3.The tank bottom is equipped with heat conduction oil heating device to prevent the temperature of bitumen falling.

4.Adopting primary coarse measurement and secondary accurate measurement makes the measurement of the bitumen more accurate.

5.The bitumen pipe and pump are both heated by conduction oil.

|

|

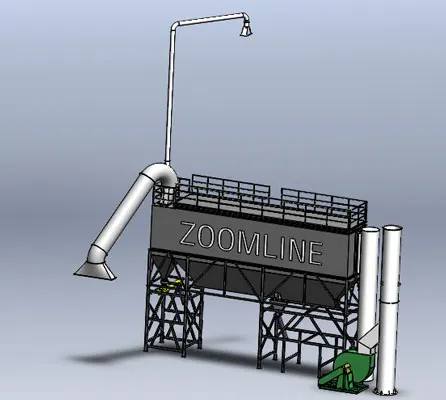

Dust collecting system

1.Combined with primary gravity dust collecting and secondary bag house dust collecting.

2.The bag house dust collecting adopts high voltage pulse cleaning with less dust residue.

3.The bag is made of DuPont high efficiency dust filtering material, with low loss and long life.

4.The recycling dust can be reused and reduce environmental pollution.

5.Emission concentration is not more than 20mg/Nm3.

|

|

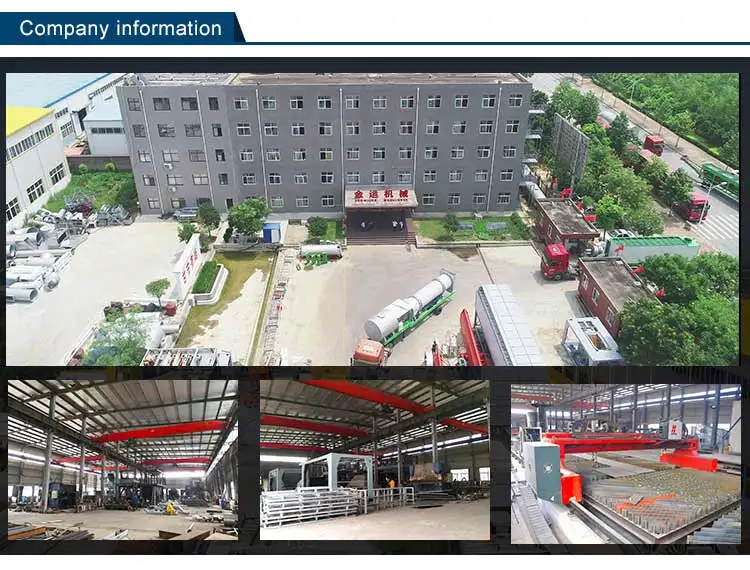

Henan ZOOMLINE Machinery Co., Ltd. is located in Nanyang Longsheng Industrial Park of Henan, China. To be a professional asphalt mixing plant, recycling asphalt plant, bitumen equipment supplier, we have one R&D manufacturing center which cover an area about 50,000 square meters.The leading products include stationary asphalt mixing plant, mobile asphalt mixing plant, continuous drum asphalt mixing plant, which are widely used in highway, city road, bridges and air port.

ZOOMLINE has the latest, highest and best goals all the time, and it puts forward--"new forms, new ideas, new initiatives, new heights, new image and new world" during the financial crisis. Undergoing rigorous training, ZOOMLINE staff combines unique management and manufacturing technology, verification of qualified processes, extensive manufacturing experience and customer foremost service spirit to produce the advanced level products.

Our main products include: Asphalt mixing plant: batch asphalt mixing plant(stationary&mobile), continuous asphalt plant (stationary&mobile), recycling asphalt mixing plant and eco-friendly asphalt mixing plant. Burner: pulverized coal burner (for asphalt plant, boiler and other industries), oil burner( heavy and diesel oil type) and gas burner for asphalt plant.We can also supply other corollary equipment, such as bitumen melting equipment, emulsified bitumen equipment, polymer modified bitumen plant, additive system, generator and road repairing machine etc.

Since ZOOMLINE start-up, we have become one of the most reliable partners of construction projects at home thorough ongoing technical investment. Our asphalt mixing plant have got high reputation for their excellent performance. Nowadays, our asphalt plant products have been sold to Russia, Cambodia, Bangladesh, Egypt, Pakistan, Uzbekistan, Kazakhstan, Kyrgyzstan, Ukraine, Georgia, Indonesia, Belgium and Thailand etc. Our asphalt mixing plants have got CE,ISO,EAC certificate.

1.The whole asphalt plant is designed according to standard high cabinet container, suitable for the construction requirement in both home and abroad.

2.All the components of this asphalt plant can be put into the container, can greatly reduce transport cost.

-

40TPH Mobile Asphalt Mixing Plant

-

Portable asphalt mixer asphalt hot recycling production pavement repair vehicle

-

Jinwang small mobile asphalt mixer road construction machinery concrete mixer

-

China famous brand 1650KG mixing capacity asphalt mixing plant SLB1500X8 for sale

-

Sell second-hand NIKKO NB1600 asphalt mixing plant

-

Mini Portable Cold Asphalt Mixer / Asphalt Mixing Plant Price / Asphalt Drum Mixing Plant 10t/h

-

asphalt mixer, asphalt mixer for mixing plant

-

UNUQUE GROUP Production 80TPH Mobile Asphalt Plant For Sale

-

20T/H - 100T/H Hot Mixing Plant Drum Mixing Asphalt Plant For Sale Continuous Asphalt Plant Price Mobile Asphalt Mixing Plant

-

LB2000 160t/h Asphalt Mixing Plant

Other Products

-

-

$20.00 - $200.00 / set

$20.00 - $200.00 / set -

$10000.00 / set

$10000.00 / set -

$350000.00 / set

$350000.00 / set -

$57000.00 / set

$57000.00 / set -

$500.00 / set

$500.00 / set -

$10000.00 / set

$10000.00 / set -

$10000.00 / set

$10000.00 / set -

$15000.00 / set

$15000.00 / set -

$200000.00 / set

$200000.00 / set