Metal steel corrugated double deck roof sheet forming machine sheet roof roll forming machine

-

Supplier: Henan Wadley CNC Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Wadley Li -

Price: $6300.00 /set -

Min. Order: 1 set

| Warranty of core components: | 1 Year; | Control system: | PLC; |

| Production Capacity: | 15 m/min; | After-sales Service Provided: | Online support,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; |

| Thickness of steel sheet: | 0.2mm to 0.8mm; | Key Selling Points: | High-accuracy; |

| Weight: | 3t; | Keywords: | Roll Forming Machine; |

| Rolling thinckness: | 0.3-0.8mm; | Port: | Qingdao;Shanghai;Tianjin;Lianyungang; |

| Diameter of shaft (solid shaft): | 70MM; | Brand Name: | WDL; |

| Dimension(L*W*H): | 6000*1400*1300mm; | Certification: | CE; |

| Roller stations: | 9/12rows of rollers; | Showroom Location: | United States; |

| Use: | WALL; | Tile Type: | colored; |

| Supply Ability: | 100 Set/Sets per Month roof sheet roll forming machine; | Type: | Tile Forming Machine; |

| Core Components: | Motor,PLC; | Cutting type: | Hydraulic Cutting; |

| Roller: | 45# Steel; | Marketing Type: | New Product 2020; |

| Payment Terms: | L/C,T/T,Western Union,MoneyGram; | Packaging Detail: | Metal steel corrugated double deck roof sheet forming machine sheet roof roll forming machine; |

| Decoiler: | provide; | Place of Origin: | Henan China; |

| Video outgoing-inspection: | Provided; | Applicable Industries: | Building Material Shops,Manufacturing Plant; |

| Feeding width: | 1220mm; | Local Service Location: | United States,Thailand; |

| Voltage: | 220V/380V; | After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; |

| Machinery Test Report: | Provided; | Condition: | New; |

| Material: | Color Steel Galvanized Plate; | Warranty: | 1 Year; |

| Color: | Client's Request; |

Metal steel corrugated double deck roof sheet forming machine sheet roof roll forming machine

| roll forming machine specs |

| 1. Dimensions: length 6000mm × width 1400mm × height 1300mm 2. Maximum speed of molding machine: 15 meters per minute 3. Forming color steel plate thickness: 0.2-0.8mm 4. Roller shaft diameter: 70mm 5. CNC computer operation panel 6. The unit includes: forming machine, hydraulic station, discharging rack, forming shears and control box. 7. Machine weight: about 3.0 tons, 8. Transmission mode: 1 inch chain drive 9. Forming row number: 4 peak tile type 13 row 5 peak tile type 11 row 10. Power host: 3kw 11. Pump station motor: 3kw 12. Distribution: The whole machine is controlled by industrial computer PLC; 13. Equipment chassis: 300H steel; vertical plate thickness is 14mm 14. Maximum error: Since the device is fully computer controlled, the maximum length error is ±1mm; |

Roll forming machine production line:

Material feeder→Molding core→Hydraulic system→Automatic control system→Automatic shearing maechanism→Roll forming receiving tables

Roll forming machine different angle pictures

it main 2 parts, body&feeding part

body including rollers, shaft ectss..,

|

|

Roll forming mahcine more details

|

PLC: easy to opearte, for the lanuage can be customzied. Of course, PLC brand can also install it according to your requests |

|

| feeding |  |

|

roller: 45#, can be OEM |

|

|

hydraulic cutting prorect your coil good when cutting

|

|

|

travel switch control coil length, the length can adjust according to people' requests |

|

If you want to do many different panell, we can customzied for you, 2 layer, 3 layer, 4 laeys ectss

save your factory spaces

| double layer |  |

| three layer |  |

Roll forming more pictures:

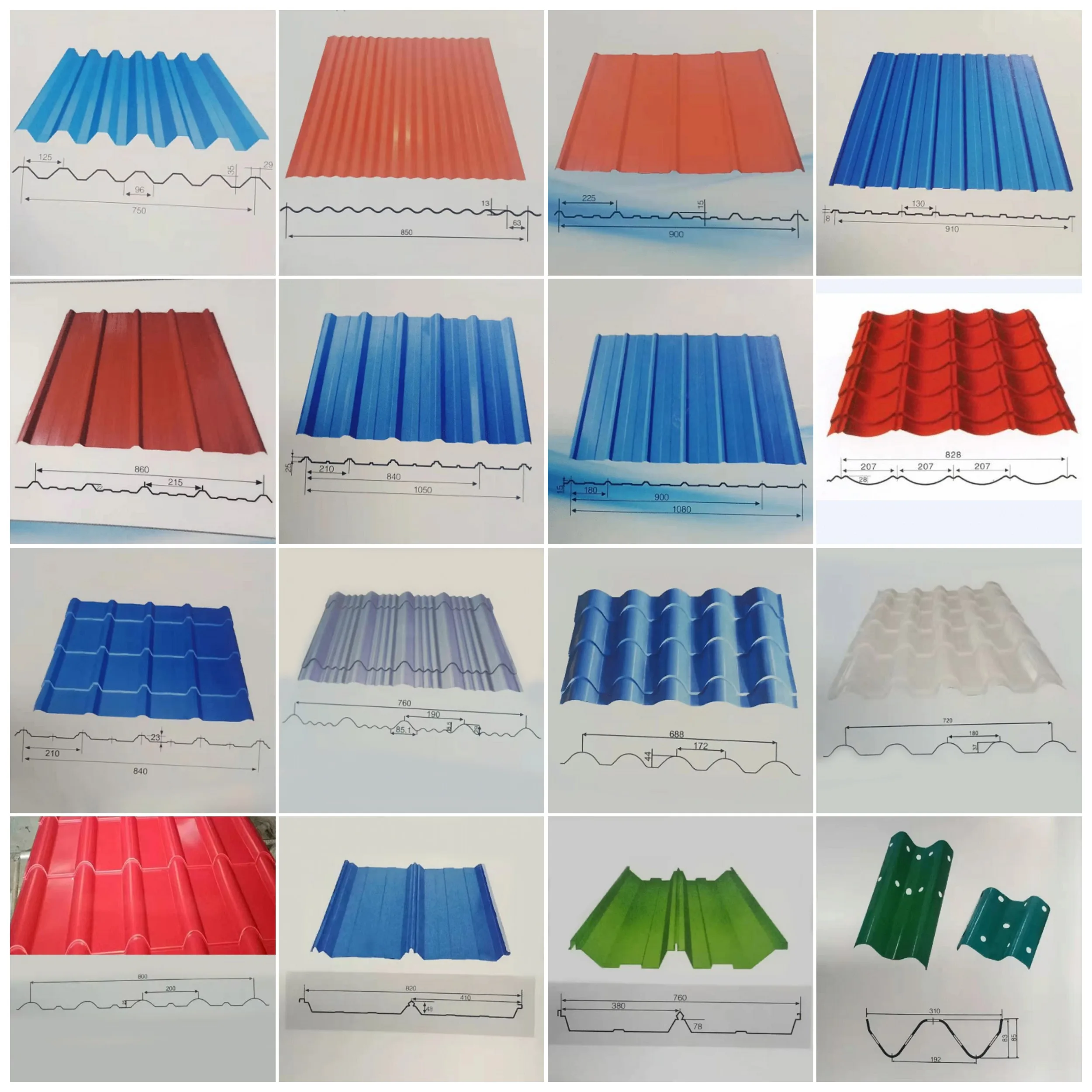

all can be customzied, just send you panel layout

Popular panel

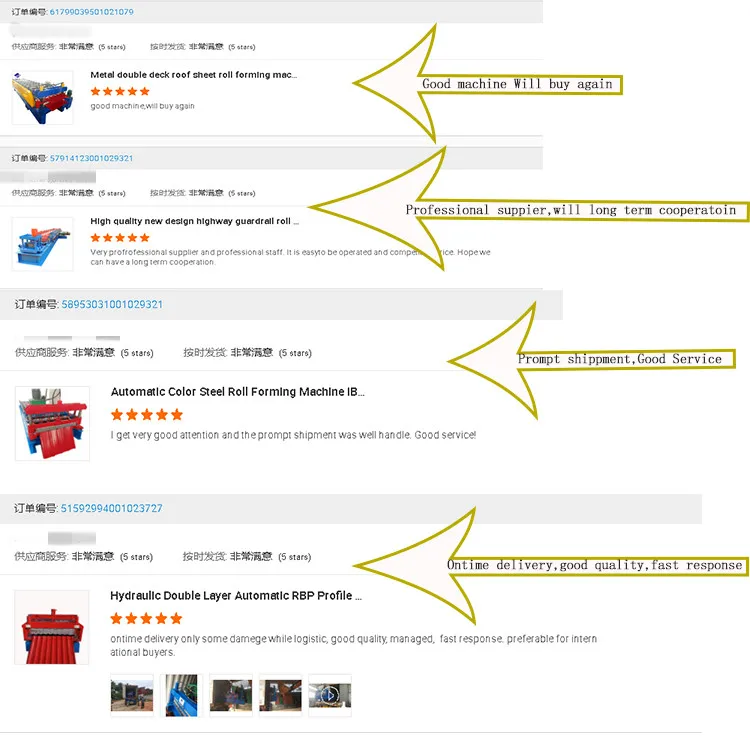

customers' feednack

|

|

Roll forming machine

good comments

Decoiler machine

| hydraulic | manual |

|

|

roll forming machine:

machine size is big, usually shipped by full container, 20GP, 40HQ, which is the suitable for this machine.

It can protect machine good too~~

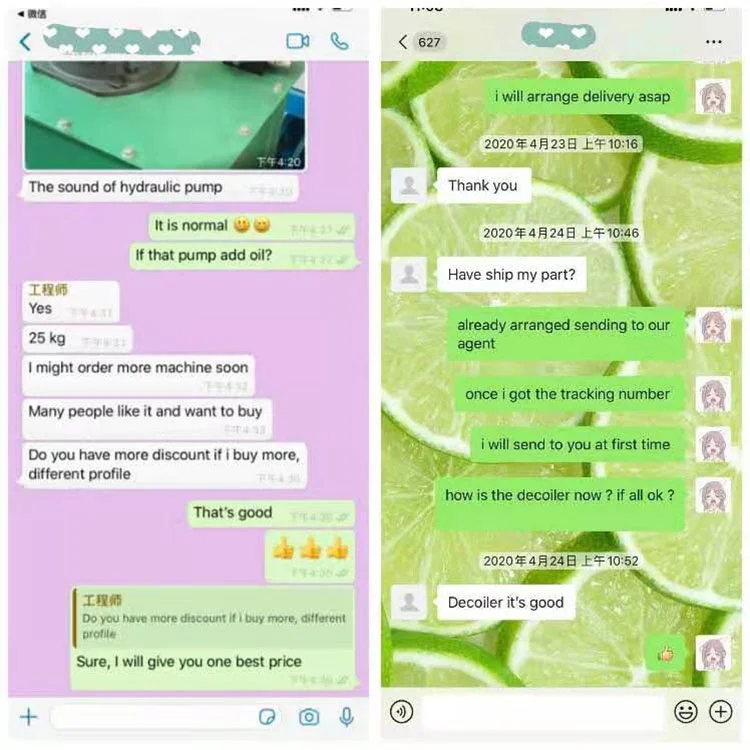

Customers' feedback below

|

|

1. If you can customized the glazed tiles forming machine for i need?

-

Three-layer molding machine

-

Low cost clay brick making machine manual type clay brick making machine suitable for different sizes and different types of bricks

-

1000 type roof panel glazed tile pressing machine

-

HMS900 Electric Tile Cutter with CE Certification 1000mm Cutting Length, Marble Saw

-

Sheet metal building materials manufacturing machinery parts

-

Wall and color steel tile type polyurethane sandwich roof panel manufacturing machine

-

Terrazzo brick press

-

2022 Popular Manual Clay Roof Tile Making Machine Floor Tile Making Machine Roof Floor Tile Press Forming Machine

-

Galvanized floor deck forming machine

-

Automatic metal Ibr shingle trapezoidal shingle roller press machine for sale in South Africa

Other Products

-

$1800.00 - $2600.00 / set

$1800.00 - $2600.00 / set -

$6500.00 - $7300.00 / set

$6500.00 - $7300.00 / set -

$475.00 - $500.00 / set

$475.00 - $500.00 / set -

$7200.00 / set

$7200.00 / set -

$7500.00 / set

$7500.00 / set -

$5900.00 / set

$5900.00 / set -

$5390.00 / set

$5390.00 / set -

$7200.00 / set

$7200.00 / set -

$1280.00 / set

$1280.00 / set -

$1500.00 / set

$1500.00 / set